Yaş ve UV Boyama Makinaları

UV Kaplama Ekipmanının Uygulamadaki Faydaları

Hız ve Verimlilik: Çelik ve alüminyum yüzeylerde hızlı sertleşme süreci ile üretim sürelerini kısaltır ve duruş sürelerini en aza indirir.

Dayanıklılık: Gelişmiş çizilmelere karşı direnç, yüksek parlaklık ve bitmiş ürünlerin ömrünü uzatır.

Çevresel Faydalar: Düşük VOC içeren çevre dostu kaplamaların kullanımıyla daha sürdürülebilir üretim yöntemlerine katkı sağlar.

Maliyet Etkinliği: Geleneksel kaplama yöntemlerine kıyasla daha düşük enerji tüketimi ve malzeme israfı sunar.

Kalite ve Tutarlılık: Çelik ve alüminyum yüzeylerde minimum kusur ile yüksek kalitede ve tekdüze bir kaplama sağlar.

UV Kaplama Ekipmanının Uygulamaları

Çelik ve Alüminyum Üretimi: Profiller, levhalar ve diğer metal parçalar üzerinde kaplama uygulamaları.

Otomotiv: Araç parçaları ve aksesuarları için koruyucu kaplama.

Elektronik: Metal cihazlar ve bileşenler için dayanıklı koruyucu kaplama.

Ambalajlama: Metal ambalajlar için estetik ve koruyucu yüzey kaplamaları.

Sanayi Ürünleri: Mobilya ve diğer endüstriyel ürünler için dekoratif ve koruyucu kaplamalar.

UV Kaplama Ekipmanının Türleri

- Airless Boya Uygulama Sistemleri

- Vakum Boya Uygulama Sistemleri

Rulo Tipi Baskı ile Boya Uygulama Sistemleri

Verimliliği ve Dayanıklılığı UV Kaplama Ekipmanları ile Maksimize Edin

Günümüz hızlı üretim ortamında, yüksek kaliteli yüzeyler ve verimli üretim süreçlerine duyulan ihtiyaç hiç bu kadar kritik olmamıştı. UV kaplama ekipmanları, işletmelerin üstün yüzeyler elde etmelerine, artan üretim hızlarına ve çevre dostu uygulamalara ulaşmalarına yardımcı olan ileri teknoloji bir çözümdür. İster baskı, ambalaj, otomotiv veya elektronik sektöründe olun, UV kaplama teknolojisi ürünlerin kaplanma biçimini dönüştürerek geleneksel kaplama yöntemlerinin karşılayamayacağı bir dizi fayda sunmaktadır.

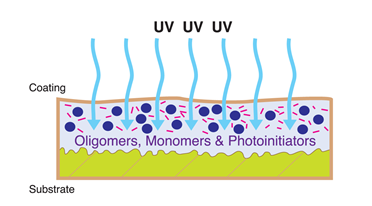

UV Kaplama Nedir?

UV kaplama, malzemelere uygulanan özel bir kaplamayı ultraviyole (UV) ışığı kullanarak sertleştiren benzersiz bir süreçtir. Sıcaklık veya hava ile kuruma gerektiren geleneksel kaplamaların aksine, UV kaplamalar UV ışığına maruz kaldığında anında sertleşir, böylece çizilmelere, aşınmalara ve diğer çevresel aşınmalara karşı dayanıklı, pürüzsüz ve dayanıklı bir yüzey oluşturur.

Sonuç, baskılı materyaller, elektronik parçalar veya otomotiv bileşenleri olsun, ürünlerinizin görsel çekiciliğini ve dayanıklılığını artıran yüksek kaliteli, parlak bir yüzeydir.

Neden UV Kaplama Ekipmanını Seçmelisiniz?

UV kaplama ekipmanları, verimlilik, kalite ve çevresel sorumluluk arayan işletmeler için bir oyun değiştiricidir. UV kaplamayı üretim sürecinize dahil etmenin bazı önemli avantajları şunlardır:

- Hız ve Verimlilik

UV kaplamanın en büyük avantajı, hızlı bir şekilde çalışmasıdır. Geleneksel kaplamalar uzun kuruma süreleri gerektirir, bu da üretimi yavaşlatabilir ve işletme maliyetlerini artırabilir. UV kaplamalar ise UV ışığı altında anında sertleşir ve üretim süresini dramatik şekilde kısaltır. Bu hızlı sertleşme süreci, daha az bekleme, daha fazla çıktı ve nihayetinde daha yüksek verimlilik anlamına gelir.

- Gelişmiş Dayanıklılık ve Yüzey Kalitesi

UV kaplamalar, geleneksel yüzeylere kıyasla üstün dayanıklılık sunar. Sertleştirildiğinde, kaplama, ürünün görünümünü ve işlevselliğini korumaya yardımcı olan sert, çizilmelere karşı dayanıklı bir katman oluşturur. Parlak ambalaj, pürüzsüz baskılı materyaller veya otomotiv parçaları olsun, UV kaplamalar ürünlerinizin zamanla kalitesini korumasını sağlar.

- Çevre Dostu

UV kaplama, çevresel etkisini azaltmak isteyen üreticiler için daha sürdürülebilir bir seçimdir. Geleneksel kaplamaların atmosfere uçucu organik bileşikler (VOCs) salması ile karşılaştırıldığında, UV kaplamalar düşük VOC seviyelerine sahiptir, bu da daha temiz hava ve daha az çevresel etki sağlamakta katkı sunar. Ayrıca, enerji gereksinimlerini azaltan bu süreç, uzun kuruma süreleri veya yüksek sıcaklık fırınları gerektirmediğinden daha az enerji kullanır.

- Maliyet Etkenliği

Kuruma sürelerini kısaltarak ve enerji yoğun süreçler gereksinimini azaltarak, UV kaplama sistemleri işletmelerin işletme maliyetlerini düşürmesine yardımcı olur. Dahası, UV kaplamalar daha hassas bir şekilde uygulanır, israfı azaltır ve yalnızca gerekli miktarda kaplama kullanılır. Bu faktörler, UV kaplamayı verimli ve maliyet açısından etkili bir çözüm hâline getirir.

- Tutarlı ve Yüksek Kalite Sonuçlar

UV kaplama teknolojisi, her seferinde tutarlı, yüksek kaliteli sonuçlar sunar. Sertleşme süreci, her ürünün eşit, kusursuz bir yüzey almasını sağlar, böylece kusur ve tutarsızlık şansını azaltır. Bu güvenilirlik, kalitelerini korumak isteyen şirketler için kritik öneme sahiptir.